Blog

How To Start A French Fries Plant In India?

time:2019-04-18 Editor:Emily

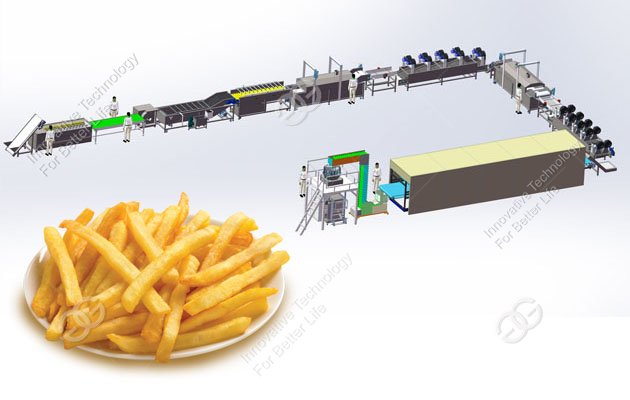

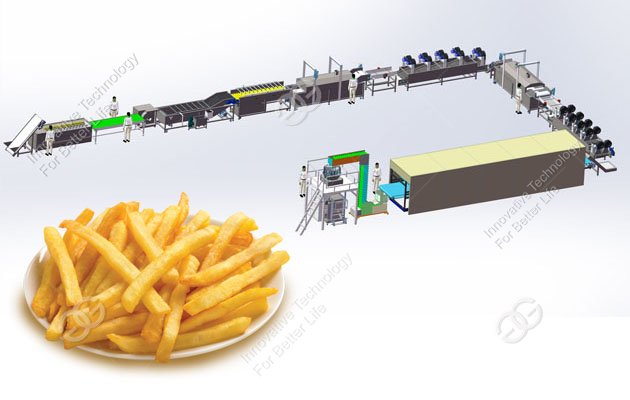

If you want to open a french fries production plant in India, then you should first understand the french fries production process, our company provides the french fries production formula for you for free, and recommends you the automatic french fries production line.This fully automatic french fries production line is suitable for mass production and is the best choice for large scale french fries production enterprises.Of course, if you are just starting the french fries business or a small french fries production enterprise, we also provide small scale french ffries production line.The output of our production line can be customized according to the needs of customers.

Do you know the French Fries Production Process?

Lifting material--Potato washing and peeling--french fries cutting--blanching--Dewatering--Continuous frying--Deoiling--Seasoning--Packing

Washing snd peeling mahchine:Brush cleaning and peeling machine, using the principle of spiral brush roller and product friction peeling, can complete cleaning and peeling work at the same time. High efficiency and low loss.

Cutting machine:The machine can be cut potato into strips or slices. The thickness of the slice and the size of the cutting strips can be adjusted at will.

Blanchine machine:The cut potato chips (strips) are rinsed and clor protected to reduce the frying time of the french fries.

Dewatering machine:Dehydration by centrifugal force. Dehydration before frying can greatly shorten the frying time and improve the taste of the potato chips. Improve production efficiency and reduce production costs.

Continuous frying machine:This equipment is an advanced frying equipment. Because the specific gravity of water and oil is different, the water is below, the oil is fried in the upper layer, and the residue is directly deposited in the water. The oil does not emit black smoke, which greatly prolongs the life cycle of the oil and greatly reduces the cost. The oil temperature control ensures the quality and taste of the potato chips. After the work is finished, the water is released and the residue will flow out along with the water.

Deoiling machine:The centrifugal deoiler removes the freshly fried potato chips (strips) and overcomes the defects of high oil content and greasy mouth of the potato chips. Improve the taste of potato chips (strips).

Seasoning machine:The drum type seasoning machine is made of stainless steel. The potato chips (strips) are evenly turned during the rotation of the drum, and the seasonings are added by sprinkling or spraying. Seasoning is not easy to break.

Packing machine:When packaging, the bag is filled with nitrogen gas, which can effectively prevent the potato chips (strips) from being broken and prolong the shelf life. Inflation, packaging, and coding are completed at one time.

The video of French Fries Plant In India :

We are professional french fries production line manufacturer,our french fries production line has the advantages of low one-time investment, low energy consumption, many functions, small size, high profit, convenient use and maintenance, etc.If you have any questions,please contact to me freely.

Email:emily@machinehall.com

Phone:0086 15538388305

Website:http://www.bestfrying.com/products/fries/full-automatic-fries-line.html

Email:emily@machinehall.com

Phone:0086 15538388305

Website:http://www.bestfrying.com/products/fries/full-automatic-fries-line.html