Products

>

<

Automatic French Fries Production Line|Industrial French Fries Processing Line

Raw Material:Potato

Capacity:300-1000 kg/h

Applications: The automatic french fries production line is mainly used to makes the french fries with the high quality,this kind of french fries processing line also could used in many materials,such as potato chips,banana chips,etc.

Advantages: The automatic french fries processing line is made of high quality 304 stainless steel, with high output and labor saving.

Feature

The Description of Fully Automatic French Production Line

Fully automatic french fries production line is the essence of similar products,retain the advantages of large-scale equipment for enrichment,and refer to the user's feedback information throughout the design and development.It has the advantages of low one-time investment,low energy consumption, multiple functions,small size,high profit,and easy use and maintenance.The full set of automatic french fries production equipment consists of peeling, slicing (strips), blanching, dehydration,frying,degreasing,seasoning,packaging and auxiliary equipment.

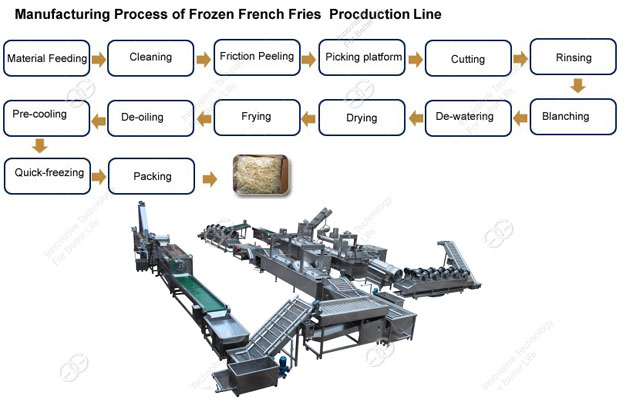

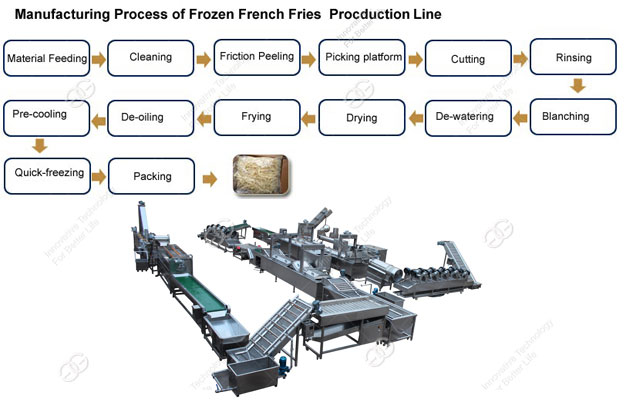

The Working Processing of Automatic French Fries Production Line

1.Cleaning and peeling machine: The use of gold steel sand lining cleaning peeling machine or brush cleaning washing machine can complete the cleaning and peeling work at the same time. High efficiency and low loss.

French fries have become one of the foods favored by many consumers because of its fast, simple and delicious taste. At the same time, frozen French fries are fast-selling fast-food products in frozen foods. After cleaning the peeled fresh potatoes, they go through the picking line and enter the cutting machine. The size of the bar can be adjusted according to customer requirements. After the blanching line, the starch on the surface of the potato bar is removed and the color of the potato bar is kept so that it is not black. After blanching, after the air line can effectively remove the moisture on the surface of the potato strips, and then enter the frying line. Frozen French fries are fried for a short time and then cooled by air-cooled drains before entering the quick-freezing machine and packaging machine. Consumers buy frozen French fries and heat for a few more minutes to eat. This speed fries are widely used in distribution centers and distribution plants in the fast food industry such as KFC, McDonald's.

The Working Processing of Automatic French Fries Production Line

1.Cleaning and peeling machine: The use of gold steel sand lining cleaning peeling machine or brush cleaning washing machine can complete the cleaning and peeling work at the same time. High efficiency and low loss.

2.Slice cutting machine: both slice and cut. Slice thickness, cutting size can be adjusted.

3.Drifting machine: The rinsing and color protection will be performed on the sliced potato chips.

4.Dehydrator: Dewatering with centrifugal force. Dehydration before frying can greatly shorten the frying time and improve the taste of potato chips. Improve production efficiency and reduce production costs.

5.Oil-water mixed frying machine: This equipment is the most advanced frying equipment. Due to the different proportions of water and oil, the water is on the bottom, and the oil is fried on the upper layer by hot chips. The residue is directly deposited in the water. The oil does not emit black smoke, which greatly prolongs the life cycle of the oil and causes the cost to drop significantly. The precise control of the oil temperature guarantees the quality and taste of the potato chips. After the work is completed, the water is released and the residue flows out with the water.

6.Deoiler: Centrifugal deoiler will deoil the freshly fried potato chips (bars) to overcome the defects of high oil content and greasy mouthfeel. Improves the taste of chips (bars).

7.Automatic seasoning machine: The drum type seasoning machine is made of stainless steel. The potato chips (strips) are uniformly turned during the rotation of the drum and the seasoning is sprayed or sprayed. Seasoning evenly and unbreakable.

8.Nitrogen filling packaging machine: When packaging, in the packaging bag filled with nitrogen, can effectively prevent the potato chips (strip) crushed, extend the shelf life. Inflate, pack and code one time.

The Advantages of Full Automatic French Fries Processing Line

The Advantages of Full Automatic French Fries Processing Line

1.The full automatic french fries production line adopts imported high-quality stainless steel material,exquisite workmanship, sturdiness and durability.

2.Intelligent digital display thermostat, convenient and practical.

3.The use of water and oil mixing technology, automatic filtration of residue, can extend the oil change cycle, greatly reducing the cost of oil.

4.Automatic temperature control, no overheating, no residue, avoiding the increase of acid price, black oil production, greatly reducing the working fumes.

5.Using partitioned temperature control, effective separation of poor quality oil, frying various foods without odor, and more than one machine.

6.With over-temperature protection device, you can use it with confidence.

Process: Oil-water separation.

The video of automatic French fries production line:

Technial Data

| Item | Parameter |

| 1, Elevator |

0.75kw/380v/50Hz 2000*800*2000mm |

| 2, Cleaning and Peeling Machine |

4.75kw/380v/50Hz 1800*900*1500mm |

| 3, Sorting Conveyor |

0.75kw/380v/50Hz 3000*900*900mm |

| 4, Potato Chips Cutting Machine |

1.5kw/380v/50Hz 950*800*950mm |

| 5, Rinshing Machine |

5kw/380v/50Hz 3500*1600*900mm |

| 6, Blanching Machine |

70kw/380v/50Hz 3500*1600*950mm |

| 7,Vibrating and Water Removing Machine |

1.5kw/380v/50Hz 1500*1000*1300mm |

| 8,Sorting Conveyor |

0.75kw/ 380V/50Hz 4000*800*1000mm |

| 9, Air Cooling and water removing machine |

15kw/380v/50Hz 4000*1200*1400mm |

| 10,Elevator |

0.75kw/380v/50hz 2500*800*1300mm |

| 11, Electric Continuous Fryer Machine |

120kw/380v/50Hz 4000*1200*2600mm |

| 12, Vibrating and Oil Removing Machine |

1.5kw/380v/50Hz 1500*1000*1300mm |

| 13,Air Drying Machine |

8kw/380v/50Hz 4000*1200*1600mm |

| 14,Elevator |

0.75kw/380v/50Hz 2400*800*2200mm |

| 15,Flavoring Machine |

50kw/380v/50hz 2500*900*1500mm |