Products

>

<

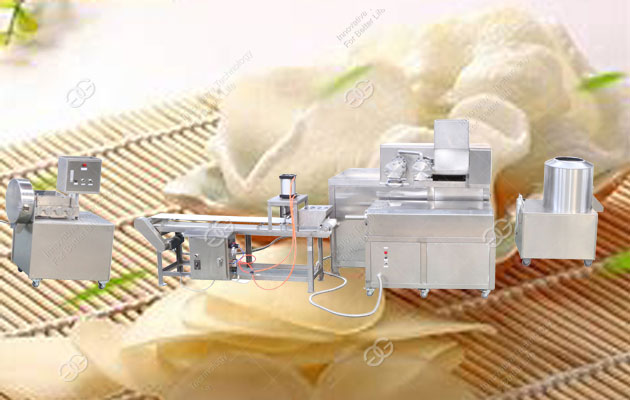

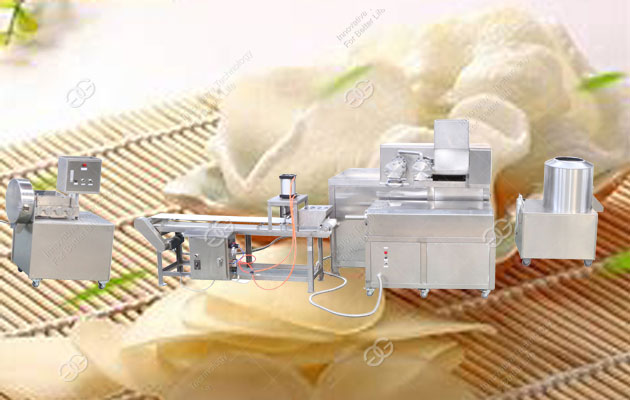

Commercial Prawn Crackers Processing Line|Shrimp Chips Production Line Price

Raw Material: Cassava starch, Wheat starch

Capacity: 300-1000 KG/H

Applications: This prawn crackers processing line is used to process wheat starch into prawn crackers.

Advantages: The production line has the advantages of high automation, large capacity, low energy consumption, small floor space, simple operation, good quality and high profit.Different output is available for customers to choose, 300-1000kg/h, the output of the machine can be customized according to the needs of customers.

Feature

The Introduction of Commercial Shrimp Cracker Production Line

Shrimp chips, also named prawn crackers, shrimp crackers, krupuk, is a kind of deep-fried snack made from shrimp and starch, popular in East Asian cuisine.

The Purpose and Scope of Use of Shrimp Chip Making Machine

This shrimp cracker making machine is special equipment for shrimp crackers production, this machine has stable performance, wide applicability and the required less operators etc, mainly use corn starch, rice and potato starch as raw material, produce different type of prawn crackers.

The Features of Commercial Shrimp Cracker Production Line

Our company provides: plant construction, raw material procurement, product formulations, product testing, equipment installation, production guidance and other one-stop service, almost meet any issues can be sold before! Based on this market demand, the company has developed and developed a variety of models of food production lines. According to the different production, the production line also has a variety of configurations to meet the needs of different customers. Its operating performance, product quality, process taste have reached the advanced level in the same industry. The production line is simple to operate, easy to understand.

The Features of Commercial Shrimp Cracker Production Line

The machine consists of feeding system, extrusion system, rotary cutting system, heating system, transmission system and control system. The use of advanced screw extrusion technology, the use of high temperature and high pressure material curing and expansion molding, one-time completion. The host adopts variable frequency speed regulation to ensure the stability of the production process. Product color, variety, appearance, natural and realistic, delicate texture, raw materials are widely used.

Installation and use of Shrimp Cracker Production Line

1.Before using curing machine, add the oil 2 liters to gear box.

2.The machine should be installed on the flat solid concrete ground.

3.Check the machine parts is complete, the bolt is strong.

4.Confirm the parts in good condition, connect power, make the machine idle run for 2-3 minutes, no other exceptions, begin to work.

5.Pour mixed starch raw material into feeding machine inside the bucket, running for 1 to 2 minutes until temperature in cylinder rise, and then adjust the feeding machine speed.

Our company provides: plant construction, raw material procurement, product formulations, product testing, equipment installation, production guidance and other one-stop service, almost meet any issues can be sold before! Based on this market demand, the company has developed and developed a variety of models of food production lines. According to the different production, the production line also has a variety of configurations to meet the needs of different customers. Its operating performance, product quality, process taste have reached the advanced level in the same industry. The production line is simple to operate, easy to understand.

Technial Data

| MODEL & NAME | SPECIFICATION |

|

Mixing machine |

Power: 3.0KW Capacity: 30kg/time/10min Size: L750*W810*H950mm |

| Extruder |

Power:18.5KW Cylinder Dia.: 100mm Capacity:80-120kg Size:L1850*W810*H1950mm |

| Re-extruding and shaping part |

Power:4KW Mold size: Can be customized Size: L850*W540*H790mm |

| Cutting machine |

Power: 3.55KW Size: L1050*W610*H750mm |